Built for the Warehouse

Smarter Perception, Safer Operations.

For industrial and material handling operators, On-Sensor [3D Zone Monitoring] transforms raw lidar data into precise, real-time collision avoidance, setting a new standard for safety and efficiency in warehouses.

A forklift with custom zones stops based on pallet detection.

- 01

Tailored Safety

Protect people and assets with 128 customizable 3D zones of any size or shape, enabling automated tailored responses through precise object detection.

- 02

Minimize Development Efforts and Costs

Firmware-native, on-sensor zone monitoring accelerates autonomy development.

- 03

Reduce sensor count in autonomy stacks

High-resolution 3D sensors with a wider field of view capture more detail, cover more scenarios, and outperform low-power 3D sensors, 2D sensors, and cameras.

3D Because the World Isn’t Flat.

Zone Monitoring: Key Use Cases

On-sensor zone monitoring leverages the advantages of 3D over 2D to improve material handling across key use cases.

Built for Autonomy, Engineered for Industry

Custom 3D Zones

Create and store up to 128 distinct 3D zones on-sensor for flexible monitoring.

Real-Time Monitoring

Actively monitor up to 16 zones with real-time statistics.

Configurable Filters

Reduce false positives in the presence of obscurants with tunable filters per zone.

Dynamic Zone Switching

Rapidly switch between active zones based on vehicle inputs such as speed and steer angle.

Parallel Data Processing

Zone Monitoring runs completely in parallel, meaning sensors simultaneously output raw point cloud data for more complex tasks.

3D Zone Monitoring is built for the real-world demands of modern material handling. As warehouses move toward greater automation, integrated sensor systems deliver the precision and reliability needed to keep operations flexible and safe. With advanced software tools for autonomy engineers and dedicated customer support for seamless deployment, Ouster is driving the next generation of warehouse automation.

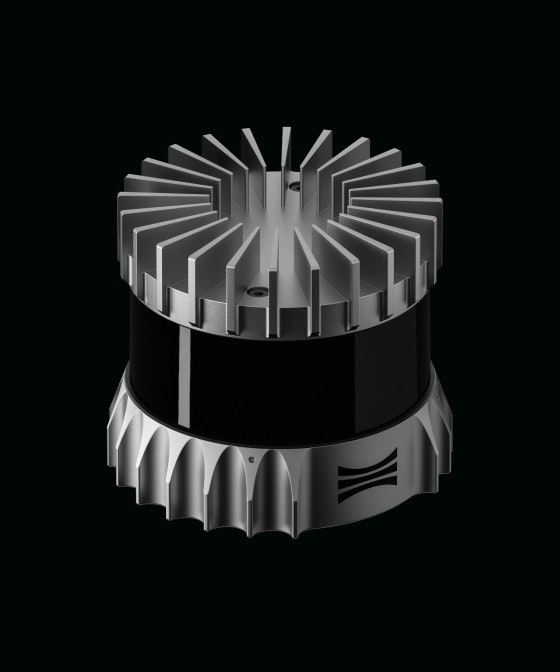

3D Zone Monitoring will be made available for the REV7 OS0, OS1 and OS Dome through Ouster’s upcoming software update (Firmware 3.2).

Contact our industrial team to learn how 3D Zone Monitoring can enhance industrial operations.

Hardware Products