The global logistics market, projected to soar to $6.55 trillion by 2027, is experiencing a profound transformation. Historically dependent on mechanical systems for the movement of goods and commodities, the industry is now shifting towards advanced technologies. This evolution is driven by an increasing demand for automation, greater operational efficiencies, and enhanced worker safety.

In Germany, where ITK Engineering (a Bosch company) operates, trucks transport a staggering three billion metric tons of goods daily, often maneuvering through the expansive and complex landscapes of container yards and docks to load and unload freight. These environments make it challenging to track the precise location of containers, trailers, and shipments. Additionally, the tendency for these areas to become quickly overcrowded exacerbates issues related to safety, dwell time, and loading efficiency.

Within these crowded and busy conditions, logistics companies are striving to address a variety of safety concerns, from speeding truck violations to navigating low visibility in busy surroundings, adverse weather, and poor lighting conditions. Drivers must perform complex maneuvers to back up to ramps and loading bays under these conditions, creating significant safety and operational challenges for both drivers and workers. The adoption of new sensor technologies, such as truck-mounted cameras and digital lidar (light detection and ranging) sensors, can streamline these tasks, propelling yard and dock logistics toward safer and more efficient operations.

ITK Engineering's Lidar-Based Solution for Safety and Operational Challenges

At ITK Engineering, a leading software and systems engineering company, our mission is to infuse intelligence into systems. An important area for our business is to solve critical hurdles faced by logistics customers:

Poor truck visibility: Many trucks lack cameras or lidar sensors. Those that are equipped with them often do not have standardized versions, resulting in inconsistent visibility

Blind spots: Fully autonomous vehicles encounter blind spots while maneuvering in the yard due to obstructions from containers or trailers they haul, which block both the driver's and sensors' fields of view

High costs to install vehicle sensors: the costs to install truck-mounted cameras or lidars to overcome blind spots is a big deterrent for many logistics companies

Our lidar-based solution aims to overcome these limitations, enhancing both visibility and safety, as well as operational efficiency in logistics environments.

Ouster Gemini for Yard and Dock Logistics

After a stringent evaluation of technology and providers, we selected Ouster’s digital lidar sensors in combination with Ouster’s Gemini perception software. By collaborating with Ouster, we are revolutionizing container depots with our dynamic, sensor-integrated assistance system, Dysi. Unlike traditional approaches that equip vehicles with cameras or lidar sensors, we have developed a scalable and stationary, infrastructure-based solution. This approach involves installing Ouster digital lidar sensors and software at the logistics yard rather than inside vehicles.

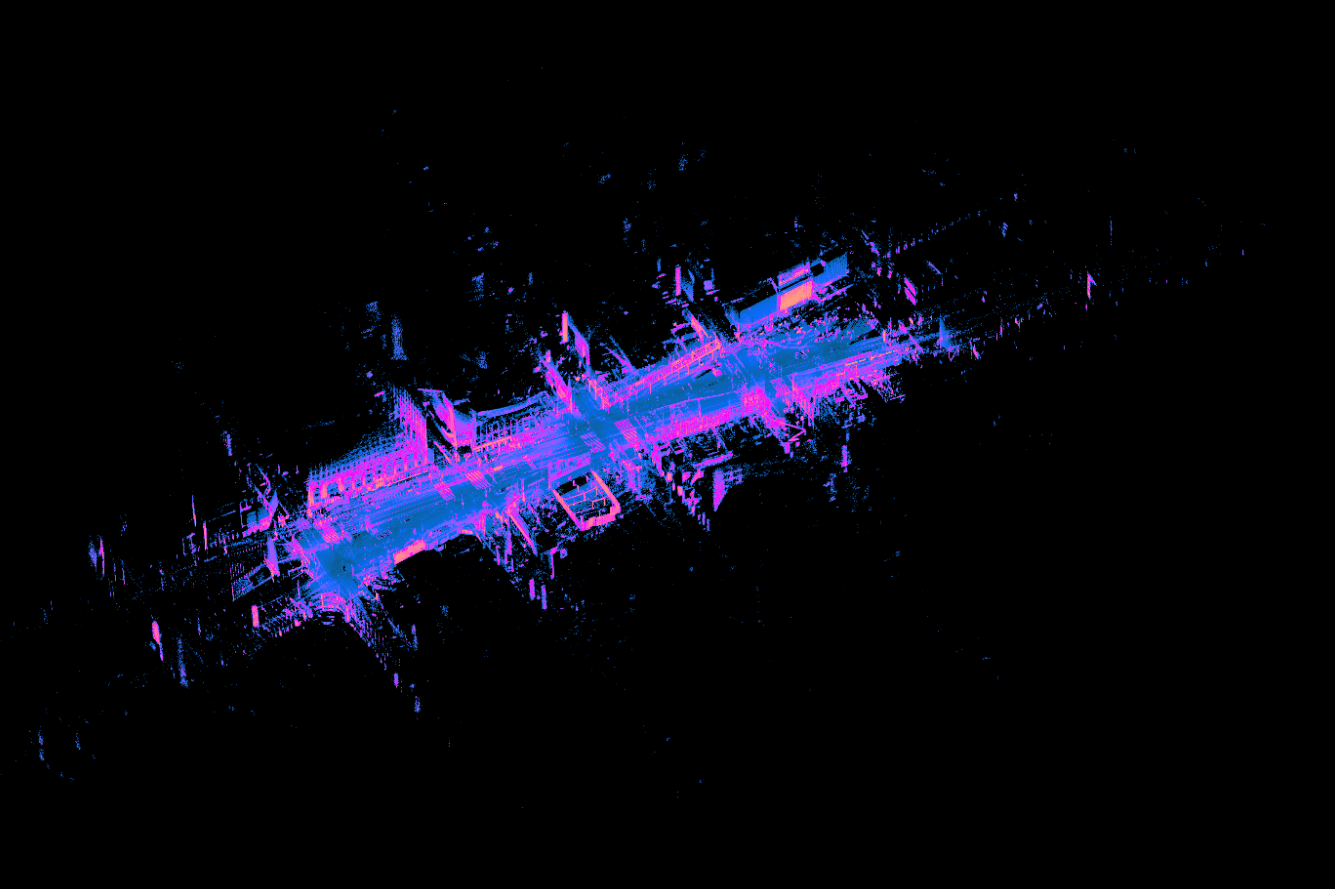

Container yard of BSH showcases the successful deployment of Ouster Gemini and Dysis app solution

Ouster Gemini in action at the BSH yard

Ensuring Privacy and Compliance with Lidar

At the BSH (a Bosch subsidiary) yard in Giengen, Germany, privacy compliance was a critical consideration. Early involvement of the Betriebsrat workers' council facilitated discussions and ensured that the solution adhered to GDPR regulations. The inherent properties of lidar technology, which does not capture personal identifiable information, made it a suitable choice for ensuring privacy.

The Advantage of Lidar Technology in Yards and Docks

Lidar technology offers several advantages over traditional cameras and motion sensors. Its 3-dimensional output and volumetric perception capabilities allow for accurate detection of objects at significant ranges, reducing false alarms and enhancing reliability. Additionally, lidar sensors perform consistently in all lighting and weather conditions, making them ideal for the varied environments of logistics yards.

Our current focus on safety could be expanded to include additional use cases, such as improving dwell times, optimizing loading operations, monitoring speed violations and perimeter security. While lidar technology may have an initial infrastructure cost, its ability to address multiple use cases ensures a quick return on investment for yard operators.

Choosing Ouster as a Partner

Our decision to partner with Ouster was driven by their advanced sensor technology and robust Gemini software capabilities. Through rigorous technology screening, Ouster emerged as a leader in the field, providing reliable and high-performance lidar solutions. Their team's expertise and innovative approach have been instrumental in the success of our Dysis system.

Future Opportunities in Logistics

Looking ahead, infrastructure-supported automated driving represents a significant advancement for the logistics industry. Autonomous trucks, in conjunction with stationary digital lidar sensors, can navigate complex yard environments more effectively. The integration of lidar with other sensors and technologies, such as 5G communication, opens up new possibilities for yard management and operational efficiency.

At ITK Engineering, we are committed to pioneering solutions that enhance safety, efficiency, and operational excellence. By leveraging the power of Ouster’s lidar and Gemini perception software, we are shaping the future of logistics, one yard at a time.