Distribution centers are the hubs of our nation’s supply chain. In the United States alone, nearly 10 billion tons of freight pass through approximately 400,000 logistics yards each year. Those billions of tons represent our daily necessities: food, clothing, consumer products, and the durable goods that keep our nation’s economy on track.

While they serve an essential function, those distribution centers are unbelievably inefficient and wasteful. For example, over-the-road semi-trucks spend more than 10 million days per year idling while waiting to pick up or unload a trailer or up to 4 hours per truck per stop.

That’s the problem Outrider is focused on solving. Improving turnaround time by just 10 minutes per truck would result in over 1 million days of additional transport time, helping to alleviate mounting supply chain bottlenecks. This would not only have a major impact on the efficiency of goods-moving, but would also dramatically reduce emissions across those distribution centers.

Outrider pioneers autonomous yard operations for logistics hubs

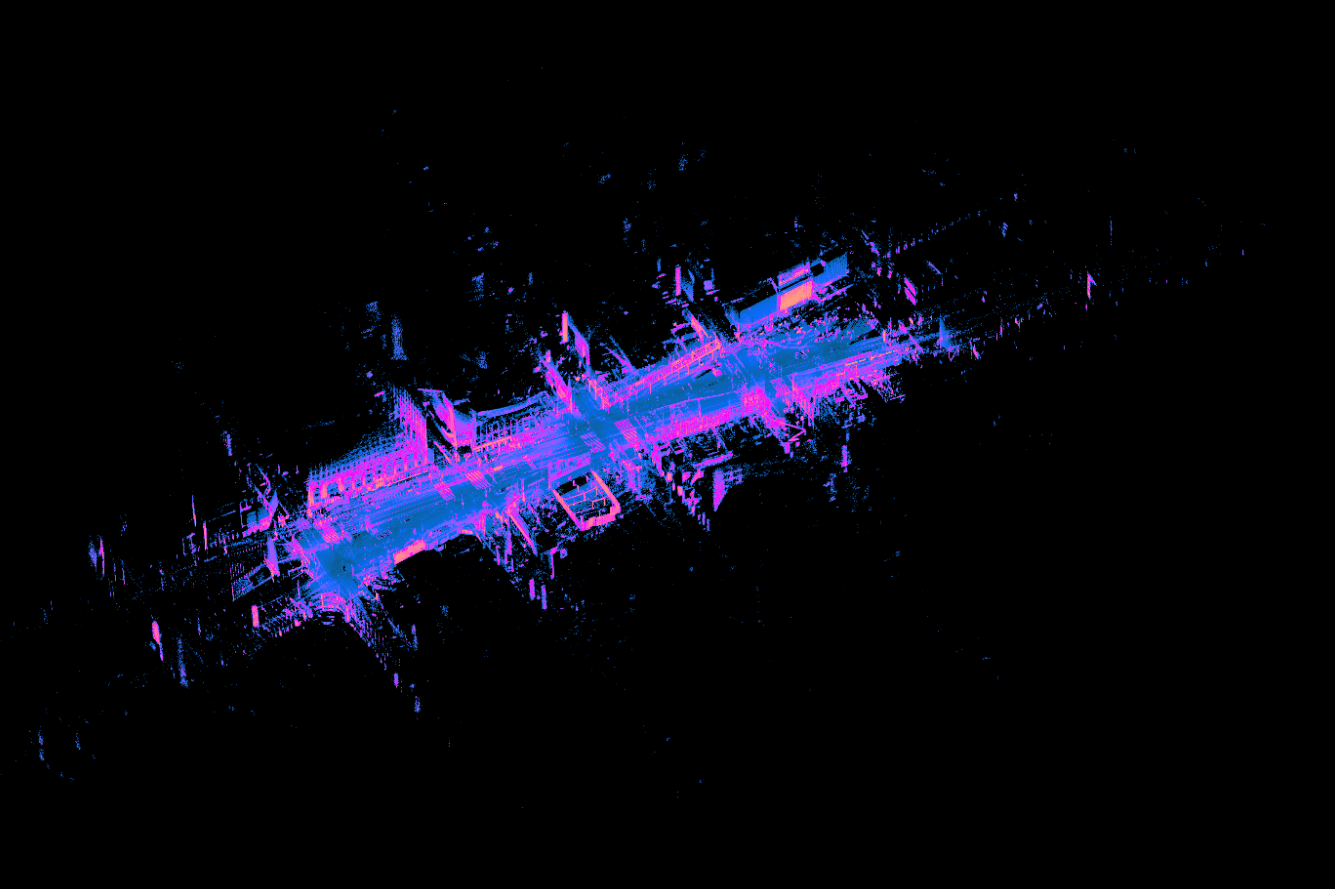

Outrider’s autonomous yard trucks are designed to address a lack of efficiency, safety, and sustainability in distribution yards. With perception powered by Ouster’s digital lidar, Outrider recently released its next-generation autonomy kit for yard operations. In addition to Ouster, the system leverages NVIDIA DRIVE’s compute architecture for system processing.

Outrider’s autonomy kit incorporates operational, design, and technical experience gleaned from over 12,000 autonomous trailer moves conducted at customer sites and its own advanced testing facility.

Digital lidar performance, reliability, and availability

Outrider selected the OS0 sensor for its ultra-wide field-of-view, allowing trucks to navigate the hitching area as well as obstacles around the yard, such as other vehicles and intersections. Additionally, the ruggedness of Ouster’s sensors was critical for performance under the harsh conditions of the distribution yards. Finally, Outrider needed sensors that were affordable and available without long lead times – all of which Ouster delivered.

“Lidar is a fundamental component of our integrated system, which enables our autonomous vehicles to see and interpret their surroundings. Having a close relationship with our ecosystem of partners is critical to maximizing the performance of the Outrider System and the throughput of our customer’s supply chains…We believe the performance and cost advantages of Ouster’s digital lidar sensors will further accelerate the industry’s rapid adoption of our technology.” – Andrew Smith, Founder and CEO

Stay in touch to learn more about Outrider and our other incredible customers.

Reach out to an expert to learn how Ouster sensors can support your industrial automation needs today.