In order to achieve some level of warehouse automation, previous generations of automated guided vehicles (AGVs) required complicated infrastructure implementations. They had a limited scope of movement which was not viable for customers, who ultimately required more flexibility and an adaptable workflow to complement their workforce.

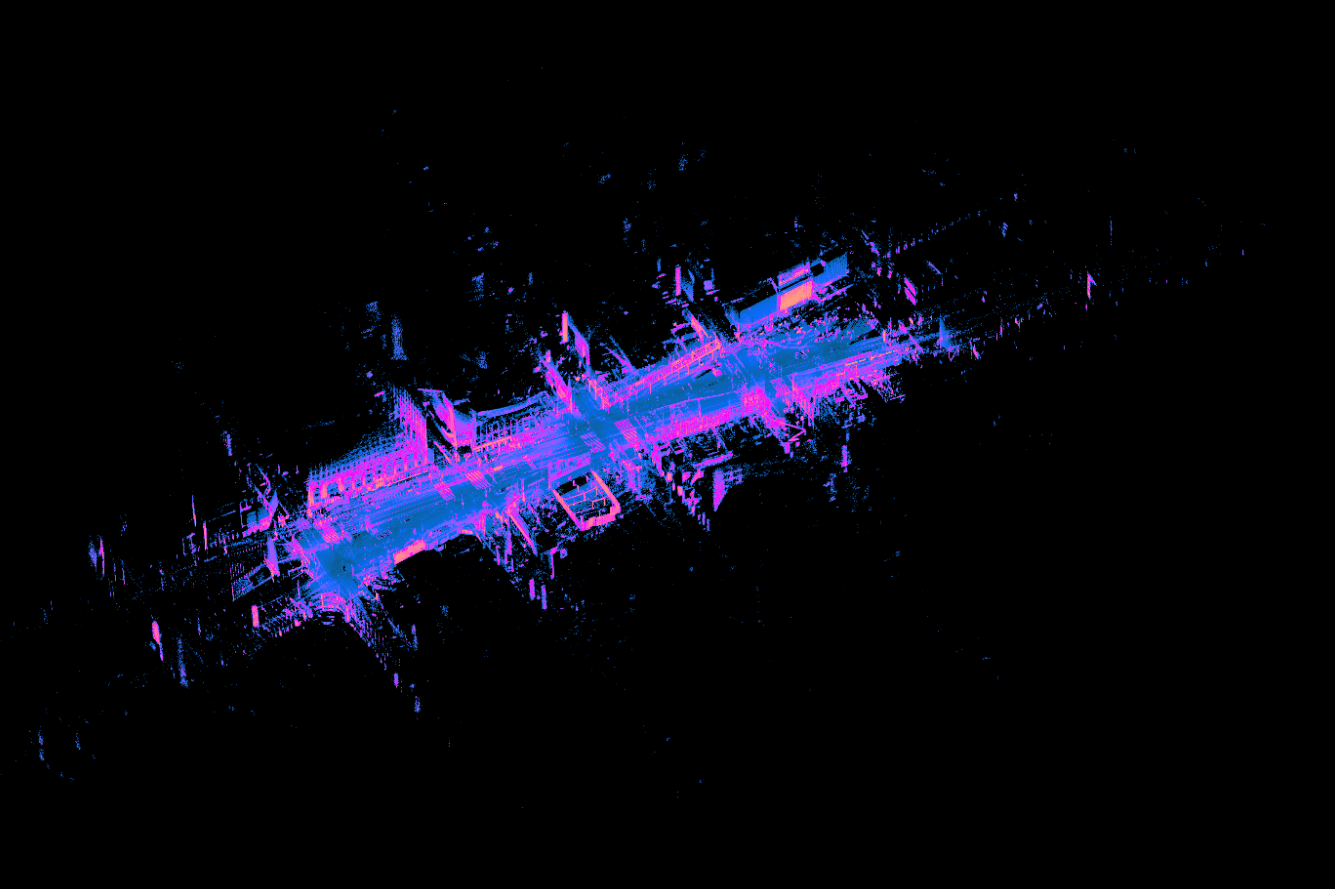

Powered by its proprietary advanced perception software and collaborative autonomy platform, Third Wave Automation combines hybrid autonomous vehicles, intelligent fleet management, remote operation, and assistance capabilities to provide holistic material handling solutions that improve over time. AGVs, such as forklifts, are equipped with up to four Ouster sensors to carry out tasks such as object detection, localization, and mapping.

The Third Wave Automation solution can be built into new material handling vehicles. The system offers the ability for vehicles to operate in manual, remote control, or fully autonomous modes, providing the end customer with flexibility in task management.

While building out their perception suite, Third Wave needed a lidar that could provide the precision that was required for busy warehouse environments with both people and forklifts in continuous and unpredictable motion. Narrow aisle configuration creates the need to sense objects extremely close to the forklift and the high resolution and wide field-of-view of Ouster’s OS0 sensor allows them to do so reliably and dependably.

I personally have been working with LiDAR sensors for almost 20 years, and we are deeply impressed with the quality, the reliability, and the availability of what Ouster is building. The wide field of view provided by the sensor we’re using is particularly impressive, and particularly valuable when automating a forklift, which has a complicated geometry that can be hard to sense. – Mac Mason, Co-Founder & Chief Robotics Officer