Warehouses are automating with increasing speed to keep pace with competition and demand. A key component of the next stage of industrial automation is robots that are able to work hand-in-hand and along with workers in all warehouse settings.

This is easier said than done. Rather than adding features to current platforms, developers need to go through full redesigns and bring new robots to market. We’ve seen this recently from Amazon robotics and their new Proteus platform.

These redesigns are happening because companies need to upgrade the sensors in their robots. Until now, most industrial sensor stacks used 2D lidar, primarily due to price. However, that low price came at the cost of performance, which will not allow them to keep up with the new stage of automation. Material handling companies designed around the poor performance by limiting the settings in which AMRs and other material handling platforms could operate. This trade-off seemed sustainable in the early stages of automation, but over time, it has created several significant problems.

- Unsafe operations Relying on 2D lidar opens industrial vehicles up to more accidents in the workplace. Missing obstacles low to the ground or above the 2D field of view can result in damage to goods or even risk to worker safety.

- Unnecessary complexity Another popular approach is to use multiple 2D lidar sensors to give better coverage and ultimately make up for the limited field of view. Adding another sensor for each area the AMR needs to detect results in a system that is expensive and overly complex to develop and maintain.

- Restricted workspace As a result of the two points above, industrial equipment that relies on 2D lidar has been limited to specific areas of operation. Restricting AMRs to small, predictable sections of warehouses free of workers and obstacles limits their efficiency and has hindered industry-wide adoption.

These pitfalls are well known in the industry and despite this, 2D lidar sensors are still being deployed in high volume simply as a cost savings measure. Today, that changes.

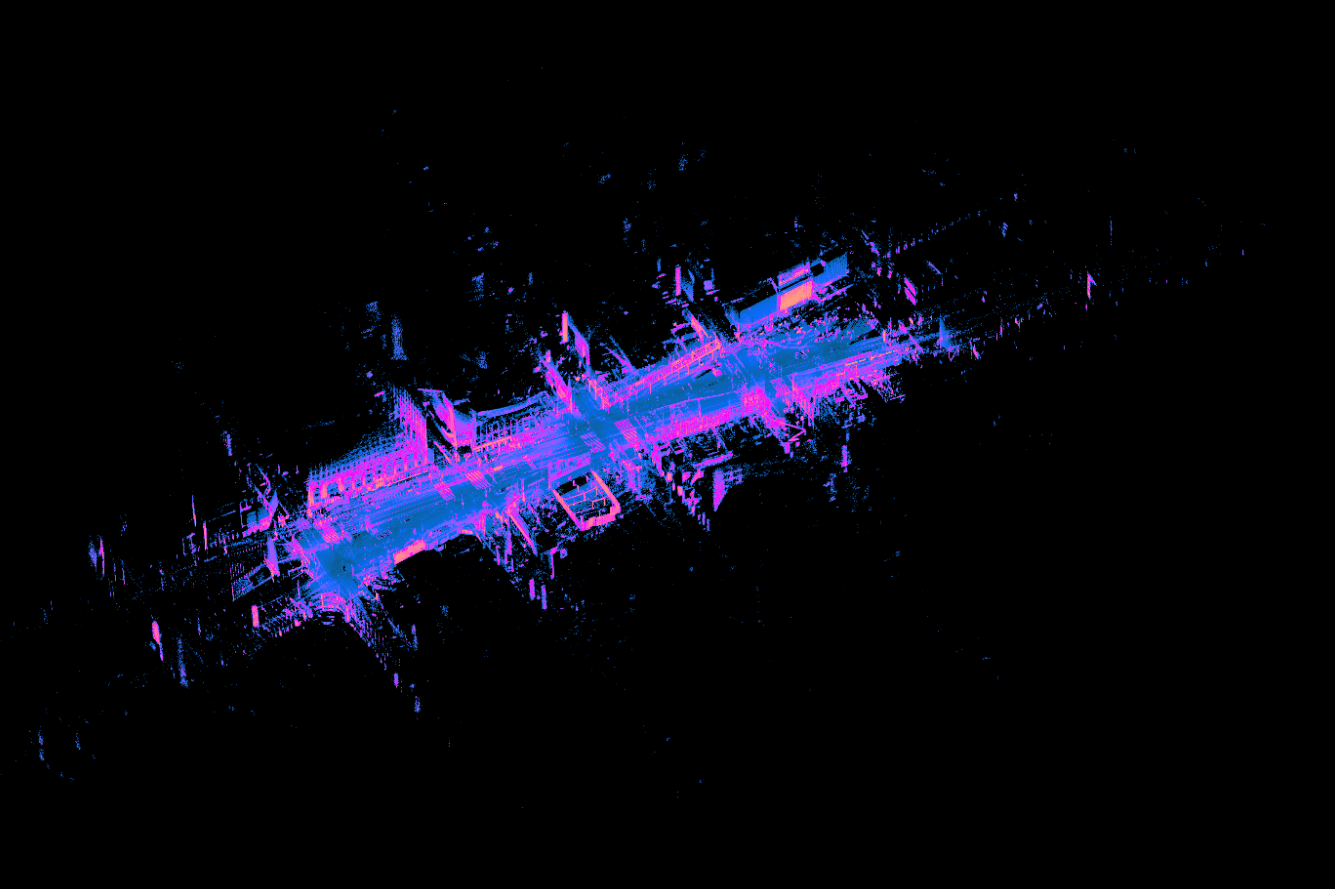

- Expanding automation with 3D lidar 3D lidar is the key to solving the challenges inherent to 2D lidar and expanding the industrial automation market. As shown in the animation above, a high-resolution 3D field of view provides a much more accurate picture of the warehouse. This additional data can help industrial robots reduce incidents, simplify systems, and expand shared workspaces – robots working hand-in-hand with workers.

- Reduce Incidents Ouster’s digital lidar provides high-resolution 3D coverage that can detect empty pallets on the floor as well as overhead obstacles. This gives a much more complete picture of the environment and results in safer operations.

- Simplify complex systems Digital 3D lidar can reduce system complexity by replacing multiple sensors with just one 3D lidar. This reduces development time, maintenance, and future-proofs machines for their next task.

- Expanding shared workspaces Shared workspaces are the key to expanding warehouse automation. Moving automation out of restricted areas to more shared spaces requires sensors that can accurately detect people. With up to 128 channels, our industrial sensors are capable of not only detecting obstacles but classifying them as well. This allows robots to expand their area of operation and work hand-in-hand with workers.

OS industrial sensor suite

In order for the industry to benefit from the advantages of 3D lidar, sensors must be built with industrial applications in mind. This is why we’re excited to announce our Industrial suite of sensors. Our OS industrial suite packages our existing digital lidar technology into a portfolio geared towards industrial applications. Utilizing our OS0 and OS1 platforms, the OS industrial sensor suite brings industrial-grade reliability, high-resolution 3D coverage, low cost, and scalability to an industry that needs to rapidly innovate. We believe the industrial suite will play a key role in expanding industrial automation and enabling the next generation of development and innovation in the warehouse and beyond.

If you are interested in learning more about our industrial sensors, reach out to us here –we’re happy to help!