Multiply the workforce.

The industrial market is the backbone of the global supply chain and easily prone to delays and disruptions. With autonomous solutions, the positive change on industry will be impactful, from how we grow food, mine resources, and build buildings to how we solve major supply and workforce challenges. Automating equipment is the key to improving labor conditions, confronting waste, reducing fuel consumption, and lowering manufacturing costs. With Ouster’s high-performance lidar sensors, technology that is as rugged as it is scalable and adaptable can power the next step in industrial automation evolution.

Harsh environments require solutions that can handle

the terrain and reliably keep people out of danger.

Mining

We’re using lidar sensors to automate repetitive and dangerous tasks to keep miners out of risk and increase the efficiency of both open pit and underground mining.

Build a stronger food system that benefits all.

Agriculture

We're helping agricultural innovators solve food shortages through the next generation of industrial machines so that healthy food is accessible to everyone.

Bluewhite and Ouster

We are driven to solve the challenges that humans face – food scarcity, and labor shortages – by building a life-long solution for the modern farmer.

Bluewhite

Modern farmers.

Autonomy in the warehouse means workers can focus their effort where its really needed.

Warehouse Automation

We're reducing forklift accidents, enhancing material handling, and powering a smarter supply chain.

Tested for 30,000 hours of continuous use.

With an average product life span of over 100,000 hours, Ouster sensors are durable and reliable enough for real world deployments in climates between -40° to +65° C.

Port logistics, shipping, and yard automation.

We're increasing the safety and efficiency of the world's logistics hubs.

Avikus and Ouster

See how Avikus is using Ouster to increase the safety and sustainability of their commercial shipping and leisure boat operations.

Avikus

Safety and sustainability.

We have demonstrated that on transoceanic voyages we can reduce fuel consumption of commercial shipping vessels by 7% and carbon emissions by 4%. With over 100,000 ships in operation every year, this has the potential to make a huge impact.

Build the vehicles that do more on their own.

Specialty Vehicles.

Reliability and high resolution can unlock a whole new suite of capabilities in automation for a diversity of purpose built specialty vehicles made for operation in all environments. Snow groomers, boats, and lawnmowers are all vehicles on which Ouster sensors have already been successfully integrated to bring autonomy to all industries.

Industrial case studies to explore.

Industrial case studies to explore.

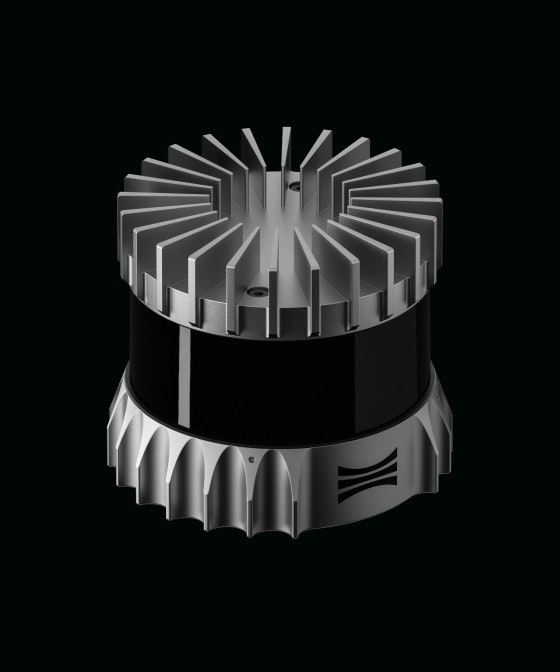

Powered by the L3.

The core of our OS lineup powers doubled range, 10x photon sensitivity, and 5.2m points per second.

Improve Safety.

Our sensors aren't just designed for accuracy. They're made to keep people safe.

Reduce cost & complexity.

Accidents and emergencies lead to unnecessary costs.

Improve efficiency.

Low maintenance and high accuracy means more efficiency.

Hardware Products