Outrider

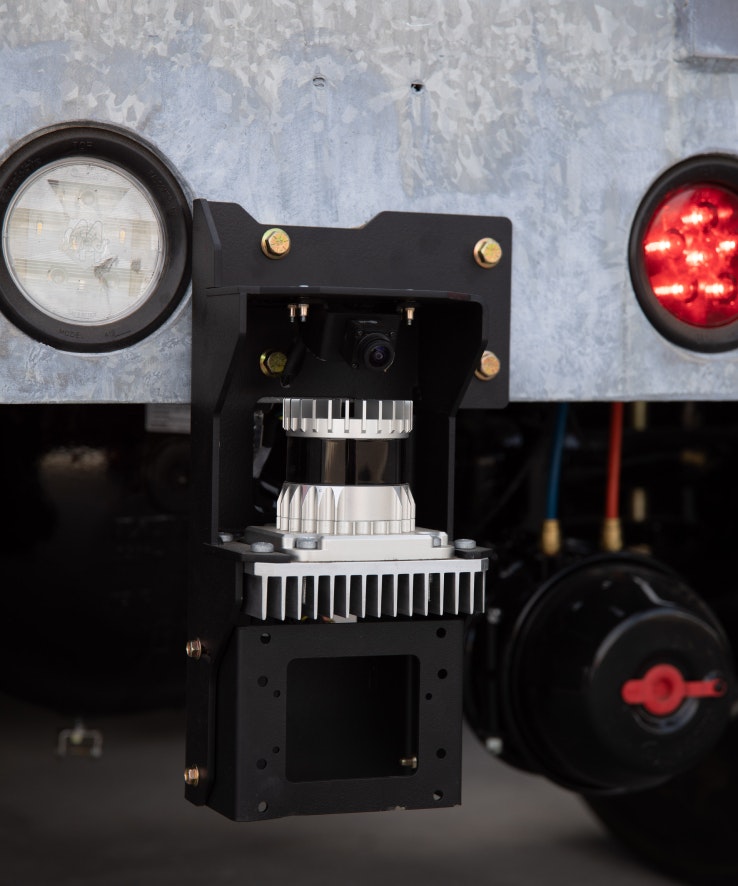

Outrider’s autonomous yard trucks are designed to address a lack of efficiency, safety, and sustainability in distribution yards. With perception powered by Ouster’s digital lidar, Outrider recently released its next-generation autonomy kit for yard operations. In addition to Ouster, the system leverages NVIDIA DRIVE’s compute architecture for system processing.

Reducing Supply Chain Friction and Emissions with Autonomous Yard Operations

Distribution centers are the key hubs of our nation's supply chain where billions of tons of freight pass through each year. These goods not only support a thriving e-commerce industry but also provide our daily necessities, including food, clothing, and other consumer and durable goods. However, these centers are plagued by inefficiencies and waste, such as the long wait times for over-the-road semi-trucks to pick up or unload a trailer, which results in more than 10 million combined days per year of unnecessary idling time equivalent to 4 hours per truck per stop.

Outrider is tackling this problem by focusing on improving turnaround times, even by just 10 minutes per truck, which would result in over 1 million days of additional transport time and help ease supply chain bottlenecks while reducing emissions across distribution centers. Automating the repetitive and wasteful tasks with electric, L4 autonomous vehicles, such as hitching and unhitching trailers and monitoring trailer locations, will free up workers to focus on more critical tasks, increasing operational efficiency and productivity.

It’s one thing to have a vehicle driving autonomously, it’s another thing to create a truly industrial system that can operate in a harsh environment over multiple years of time, 20 to 24 hours a day, 365 days a year.

The Challenge

While humans will still be essential at distribution centers, automating the repetitive and wasteful tasks with electric, L4 autonomous vehicles will free workers to focus on more critical tasks while significantly increasing operating efficiency and productivity. Time no longer needs to be spent on hitching and unhitching trailers, waiting for spaces to become free, connecting and disconnecting trailer brake lines, and monitoring trailer locations.

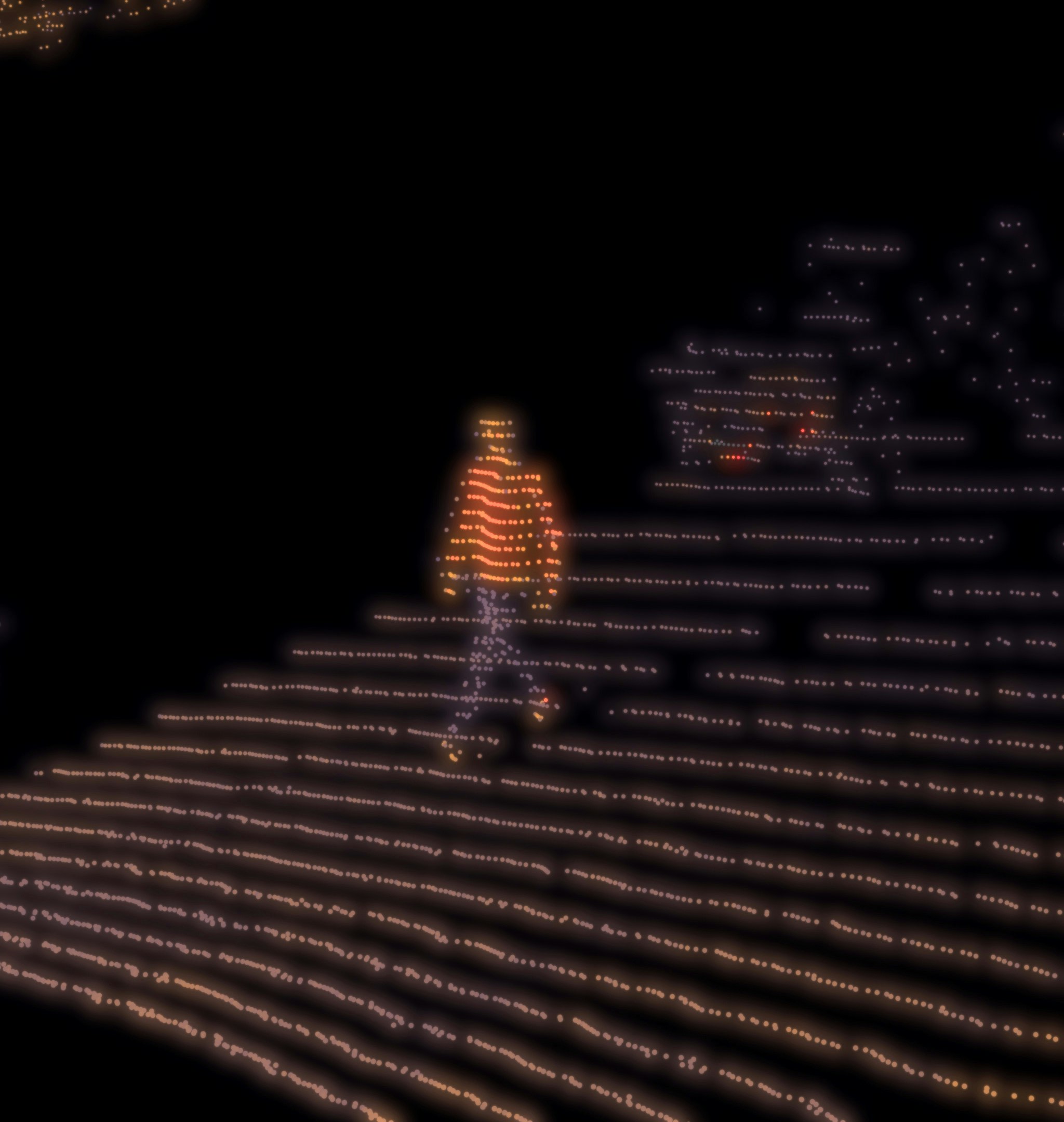

To achieve this level of autonomy, Outrider had to overcome several challenges, such as ensuring reliable perception of a yard truck's surroundings to detect both anticipated and unanticipated objects. Additionally, critical tasks that require precise centimeter-level accuracy, such as backing a trailer to a dock or hitching a trailer to a truck, necessitated the implementation of Ouster's OS0 sensors.

Adopting clean vehicle technologies is no longer a nice-to-have, it’s a must-have. That’s why since its inception, Outrider standardized its autonomous system on zero-emission electric vehicle platforms…Using clean energy vehicles in all of our commercial transportation will lead to a cleaner environment – helping us to reduce carbon emissions by 40% by 2030.

The Solution

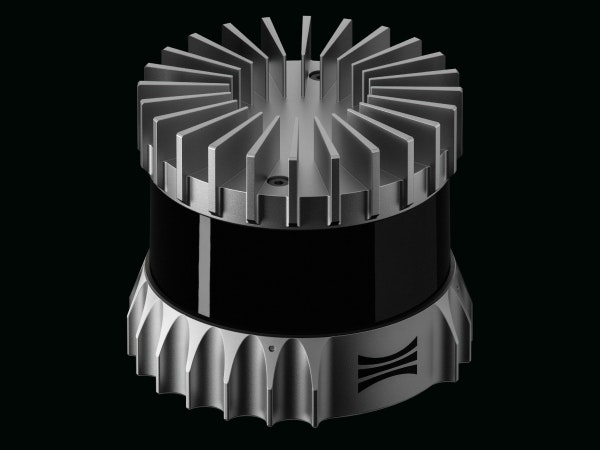

Outrider selected the Ouster OS0 for its ultra-wide 90° field-of-view, which enables trucks to navigate tight spaces and obstacles around the yard, including other vehicles and intersections. The sensor's ruggedness was also critical for performance under harsh conditions, such as snow, rain, and extreme temperatures, which are common in distribution yards that need to operate 24/7. Ouster's sensors are designed with an operating temperature range of -40 to +60°C, are certified IP68 and IP69K for ingress protection, tested for 10,000 hours of continuous operation, and provide superior visibility in rain and snow.

The REV7 OS0 provides a 35m range at 10% reflectivity and a 100m max range, making it the ideal solution for environments such as distribution centers which need both close and medium range sensing capabilities.

Finally, Outrider needed sensors that were affordable and available without long lead times. Ouster’s digital architecture and focus on manufacturable products means that sensors produced in both our San Francisco facilities and by our manufacturing partner, Benchmark Electronics, in Thailand are production ready. Ouster is uniquely positioned to provide products on demand with capacities in the thousands/month, a necessity as companies need to quickly scale.

Improving turnaround time by just 10 minutes per truck would result in over 1 million days of additional transport time, helping to alleviate mounting supply chain bottlenecks.

Results

Outrider’s next-generation autonomy kit for yard operations, powered by Ouster's digital lidar along with NVIDIA DRIVE’s compute architecture, incorporates operational, design, and technical experience gleaned from over 12,000 autonomous trailer moves conducted at customer sites and its own advanced testing facility.

The efforts have resulted in an impressive 40% reduction in traditional operating costs, a 50x improvement in cost efficiency compared to remote driving operations, and a 40% reduction in emissions, making meaningful adoption attractive from both a business and social responsibility perspective.