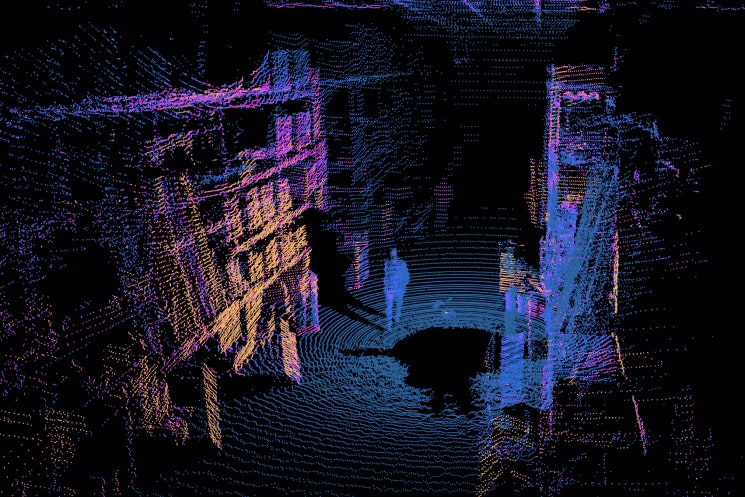

Providing reliable and dependable object detection in warehouse aisles.

Automated material handling has the potential to significantly increase efficiency and safety while lowering costs for warehouse operators around the world, translating into real world benefits for both workers and businesses. A study from the Fraunhofer Institute for Material Flow and Logistics (IML) found that automated guided vehicles (AGVs) increased warehouse productivity by up to 50% and reduced labor costs by up to 30%. Dedicated to the principle of creating a real world impact through collaborative autonomy, Third Wave Automation has set out to “multiply human potential” with their hybrid autonomous vehicles and intelligent fleet management systems that continue to improve over their lifetimes.

I personally have been working with lidar sensors for almost 20 years, and we are deeply impressed with the quality, the reliability, and the availability of what Ouster is building. The wide field of view provided by the sensor we’re using is particularly impressive, and particularly valuable when automating a forklift, which has a complicated geometry that can be hard to sense.

The Challenge

Previously, achieving a level of automation with AGVs required complicated infrastructure implementations and warehouse re-organization. Moreover, they had a limited scope of movement, which was not viable for customers, who ultimately required more flexibility and an adaptable workflow to complement their workforce. Third Wave CEO Arshan Poursohi likened the shift towards autonomous vehicles in warehouses to swapping out an engine mid-flight; “If you automate one piece of operations without thinking about the neighboring sections, you might be shifting a heavy load to a person instead of making a better system overall.”

The challenge was then to build a system that could be integrated and increase efficiency without disrupting current operations – multiplying output productivity.

To accomplish this, Third Wave had to operate in an unpredictable and busy warehouse environment occupied by both people and forklifts moving in unforseeable ways. Narrow aisle configurations within warehouses additionally created the need to sense objects extremely close to the forklift.

The Solution

In collaboration with local operators, Third Wave designed their AGVs, such as forklifts, to be equipped with up to four Ouster OS0’s in order to carry out tasks such as object detection, localization, and mapping.

While building out their perception suite, Third Wave needed a lidar that could provide the precision they demanded. The OS0 provides reliable and dependable object detection in warehouse aisles thanks to its ultra-wide 90° FoV and minimum range of 0.5m. With REV7, the OS0 extends its short range capabilities to 35m at 10% reflectivity and a maximum range of 100m, redefining what can be done in warehouse perception.

Talking to local operators early on to find out what they need better informs our technology so we can help them and solve their actual problems versus the theoretical problems we imagined in the lab.

The OS0’s 35m range and 90 degree FoV means that forklifts can see and detect objects throughout an entire warehouse aisle.

Results

The Third Wave system is highly flexible, allowing for integration into new material handling vehicles. It also offers the ability for vehicles to operate in manual, remote control, or fully autonomous modes with one controller operating up to 10 trucks. The results are an increase in the efficiency of a warehouse and the productivity of a labor force who can focus on more challenging, fulfilling, and demanding tasks.