At Ouster, we continuously improve the performance, feature set, and capability of our product portfolio while maintaining form, fit, function, and backwards compatibility of the hardware and firmware we ship.

As a result of significant hardware improvements over the past year, we’ve enhanced the reliability of our lidar sensors to keep them running longer in the most rugged, thermally extreme environments, and now we’re passing those benefits to our customers in the form of expanded warranty coverage:

- Standard two-year warranty with every new sensor, a first in the high-resolution lidar industry

- Warranties now cover cold-weather operating temperatures down to -40°C for our OS0 and OS1 models

- Optional three-year warranty add-on with each sensor purchase

The expanded warranty coverage applies to all sensors purchased on or after February 1st, 2021.

Additionally, we have made upgrades to our sensors, shipping now:

- Added top mounting holes to the OS2

- Increased the maximum operating temperature of the OS2 to +64 °C

- Increased the maximum operating temperature of the OS0 and OS1 to +60 °C

Reducing lidar’s total cost of ownership with digital lidar technology

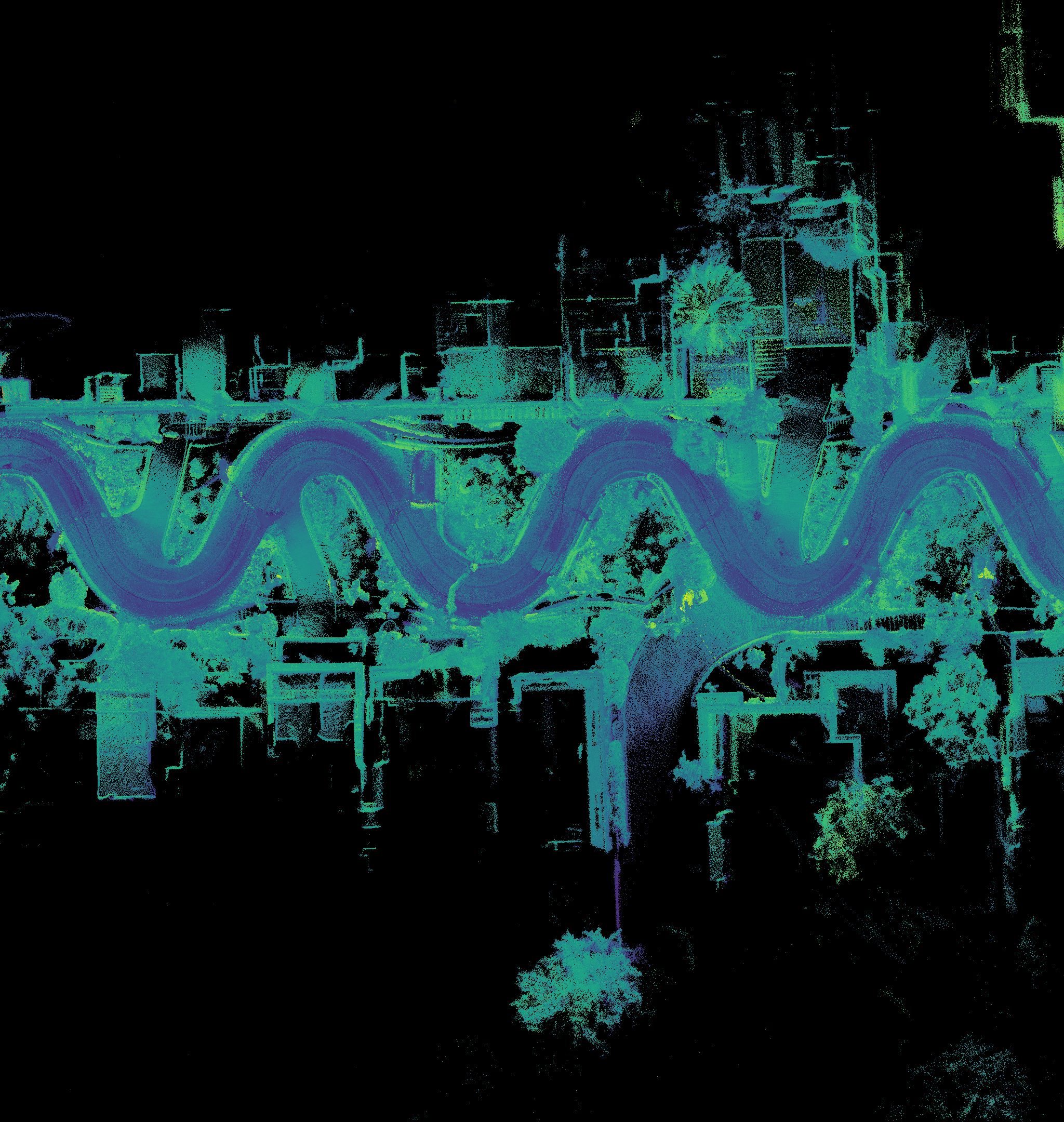

The cost of lidar is a hot topic, but a key missing component of the discussion is the impact of reliability on a lidar sensor’s total cost of ownership. When looking at the true cost of a sensor, customers can’t only consider the upfront cost. They have to consider how that upfront cost is spread out over the expected years of operation, and if there are additional maintenance costs. This is where digital lidar shines.

Analog lidar sensors can suffer from frequent failures and the need for expensive recalibration and repairs throughout their lifetime. On the other hand, Ouster digital lidar sensors have a long lifetime and do not need expensive regular maintenance along the way. With this long lifetime, and no maintenance cost, Ouster sensors can have a significantly lower total cost of ownership than analog lidar, We detail the economics of reliability in our on-demand Reliability and Ruggedness Webinar.

Ouster’s digital technology and simplified architecture are the critical enabling features that power this industry-leading reliability, ruggedness, and resulting a lower cost of ownership.

Moving towards automotive grade reliability

To achieve automotive-grade reliability, lidar sensors need to mature into highly robust devices that perform in the most challenging environments.

With cold weather performance extended to -40 °C, the OS0 and OS1 now meet the automotive spec for cold weather performance. The new standard two-year warranty, an industry-first, is also a critical milestone on our journey towards automotive grade. And finally, the introduction of an additional three-year warranty option is a sign of more to come. As we continuously improve our sensors, we plan to expand our warranty coverage over time.

How we achieved industry-leading reliability

Ouster sensors are designed to IP68/69K standards, reliably performing across unpredictable weather conditions and extended outdoor use through rain, snow, hail, dust, and fog. But that isn’t enough. Over the past year, we followed a rigorous testing and failure analysis process, analyzing every returned sensor to identify the root causes of failures and implement measures to fix them.

As a result of our efforts, over the past year we have:

- Introduced improved thermal cycling performance with better adhesives

- Improved resistance to shock and vibration with upgraded mechanical components

- Reduced minimum operating temperatures through new firmware features

- Increased maximum operating temperature with improved internal thermal design

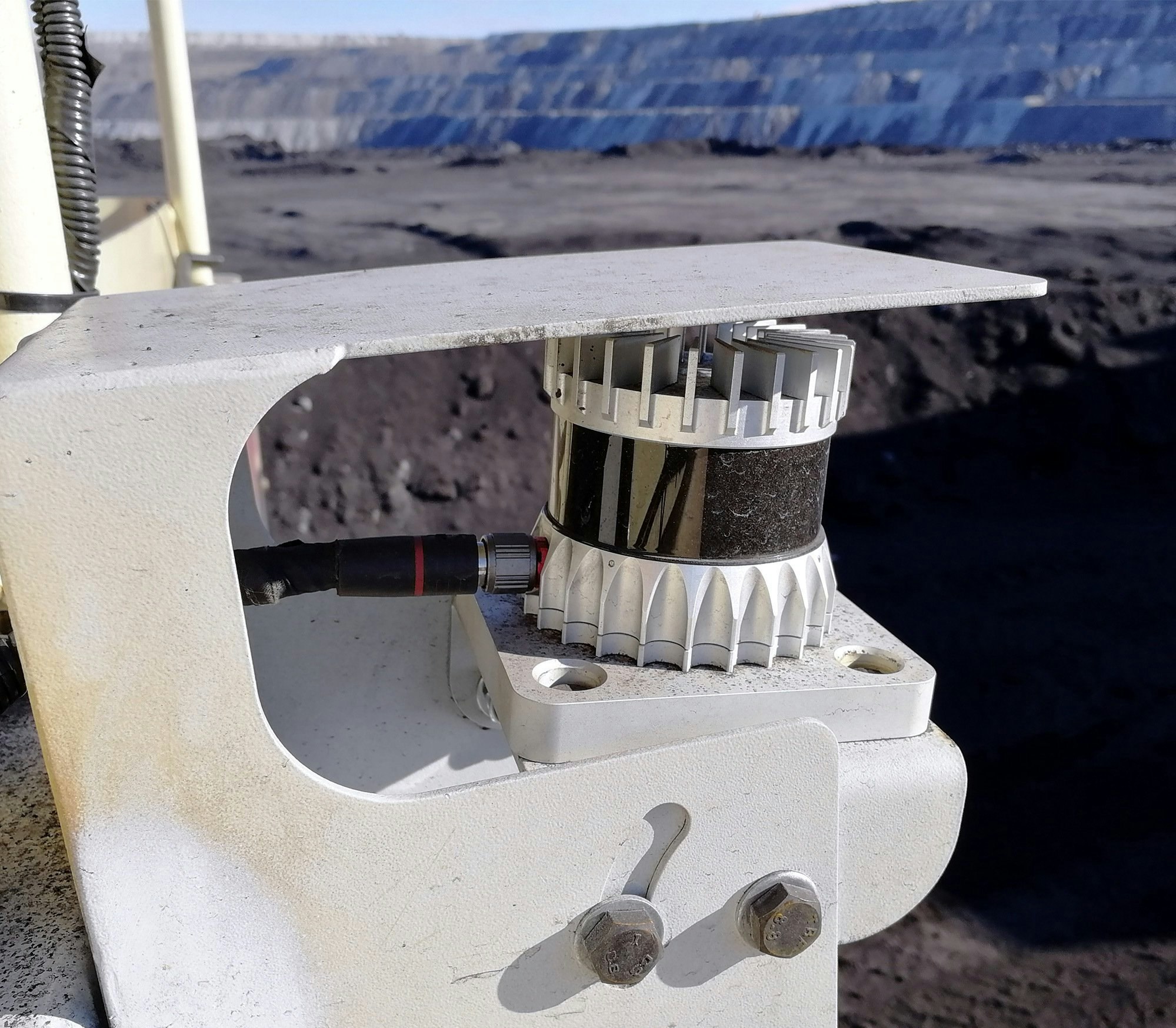

New mounting holes for OS2 models

Finally, as part of our continuous sensor improvement, we’ve also made design upgrades to OS2 models.

In addition to the reliability improvements highlighted above, new OS2 models have an updated top mount pattern to allow customers to mount the sensor from either the top or the bottom of the housing. The weight of the new sensor design is 1100 grams. The updated OS2 is available and shipping now.

Learn more

Additional details on the warranties, including terms and conditions, can be found in our Terms of Sale.

For more information about our latest sensors, please refer to our Hardware User Manual or speak with your sales representative.

Want to learn more about our sensors and how they can accelerate your projects? Connect with an expert today.