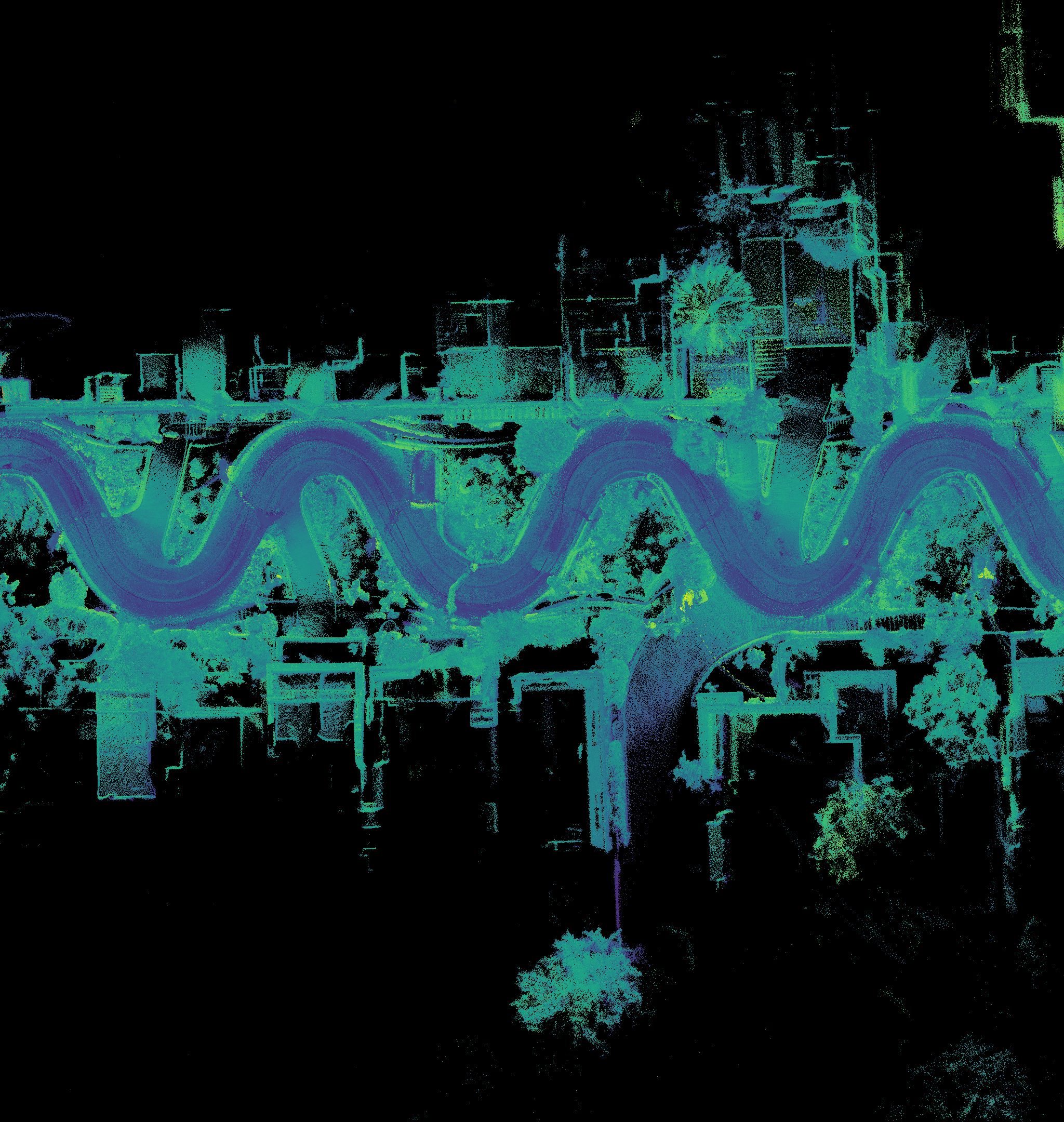

Over the last year, Ouster has made huge strides to accelerate production capacity and achieve automotive-grade specifications in preparation for commercial automotive deployment. This includes meeting automotive requirements for cold weather performance, achieving industry-leading reliability with a standard two-year warranty, and most recently, shifting the majority of our sensor production to Benchmark Electronics’ automotive-certified facility in Thailand. These are critical milestones for any lidar manufacturer looking to scale production at quality and cost to automotive standards.

Ensuring automotive-grade quality at scale

Benchmark’s Thailand facility complies with international standards that govern quality and environmental requirements for the automotive industry.

These include:

- ISO 9001:2015: guiding principles an organization must follow to demonstrate that it can consistently produce products that meet quality customer and regulatory requirements. This governs things like thorough documentation, resource management, and product development processes.

- IATF 16949: one of the most broadly used standards for quality management within the automotive industry and implemented in conjunction with ISO 9001:2015. This standard includes specific automotive requirements with emphasis on continuous improvement, defect prevention, and reduction of variation in the supply chain.

- ISO 14001: 2015: requirements around ensuring sustainable development, including ensuring processes prevent environmental impacts and compliance with environmental policies.

These regulations bring us closer to achieving ISO 26262, the international functional safety standard required for all electric products designed into road vehicles. ISO 26262 governs the entire product development lifecycle and ensures that products achieve the highest level of safety for automotive.

We have also partnered with major automotive OEMs to conduct audits of our facility on Benchmark’s Thailand campus. Completed prior to the outbreak of COVID-19, these automotive audits confirmed Ouster’s compliance with automotive quality standards and our ability to meet the OEMs’ aggressive automotive production timelines.

Achieving high-volume production

In addition to receiving automotive certifications, Ouster’s facility within Benchmark’s Thailand campus is designed to enable us to scale substantially. We have a custom microelectronics line, a full-sensor assembly line, and an end-of-line test room. With these new processes, Ouster has shipped over 2000 sensors in 2020. In Q4 2020 alone, our total sensor output across our Thailand and San Francisco facilities has increased by over 60% compared to the previous quarter.

Moving forward, Benchmark’s Thailand facility is expected to support the high volume, low cost production of Ouster sensors while meeting major industrial quality requirements and future automotive-grade qualifications. Ouster’s San Francisco facility will continue to be utilized for introducing new products and fulfilling select U.S. customer contracts.