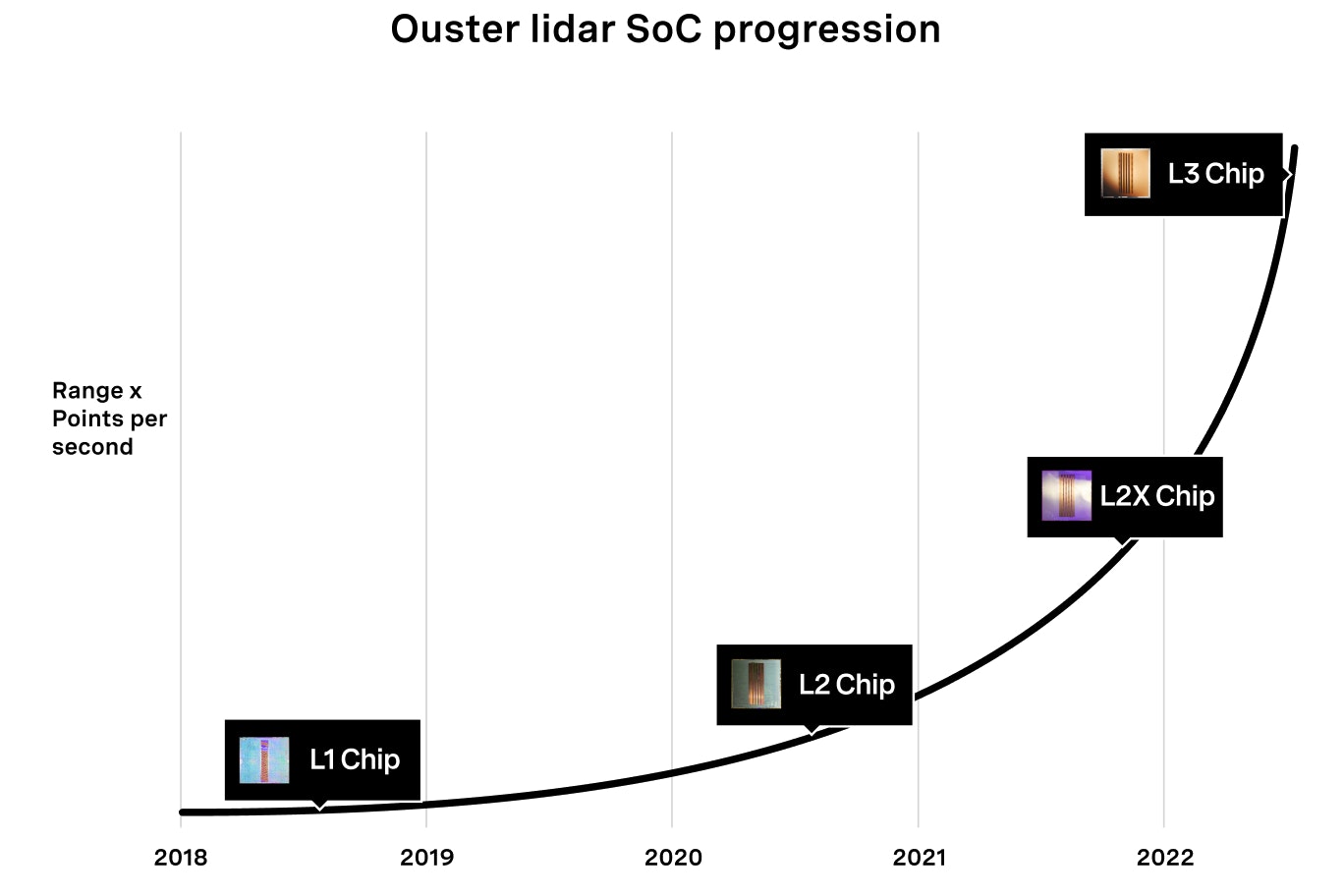

In 2015, our goal was to build the most performant and affordable lidar sensors upon the foundational principle that digital technology wins. From personal computers to mobile phones, cameras, and radar sensors - Aligning a hardware roadmap with a silicon roadmap harnesses the power of Moore’s Law to bring life-changing innovation to our everyday lives.

Since then, we have built upon our digital architecture to release new and improved sensors every year – something no other lidar company has done. Constant improvement is a trademark of digital technology and has been the catalyst for broad adoption across electronic applications.

Over the past 7 years, we have leveraged the proven advantages of digital technology to deliver thousands of sensors to over 600 customers across the globe. But that was just the beginning.

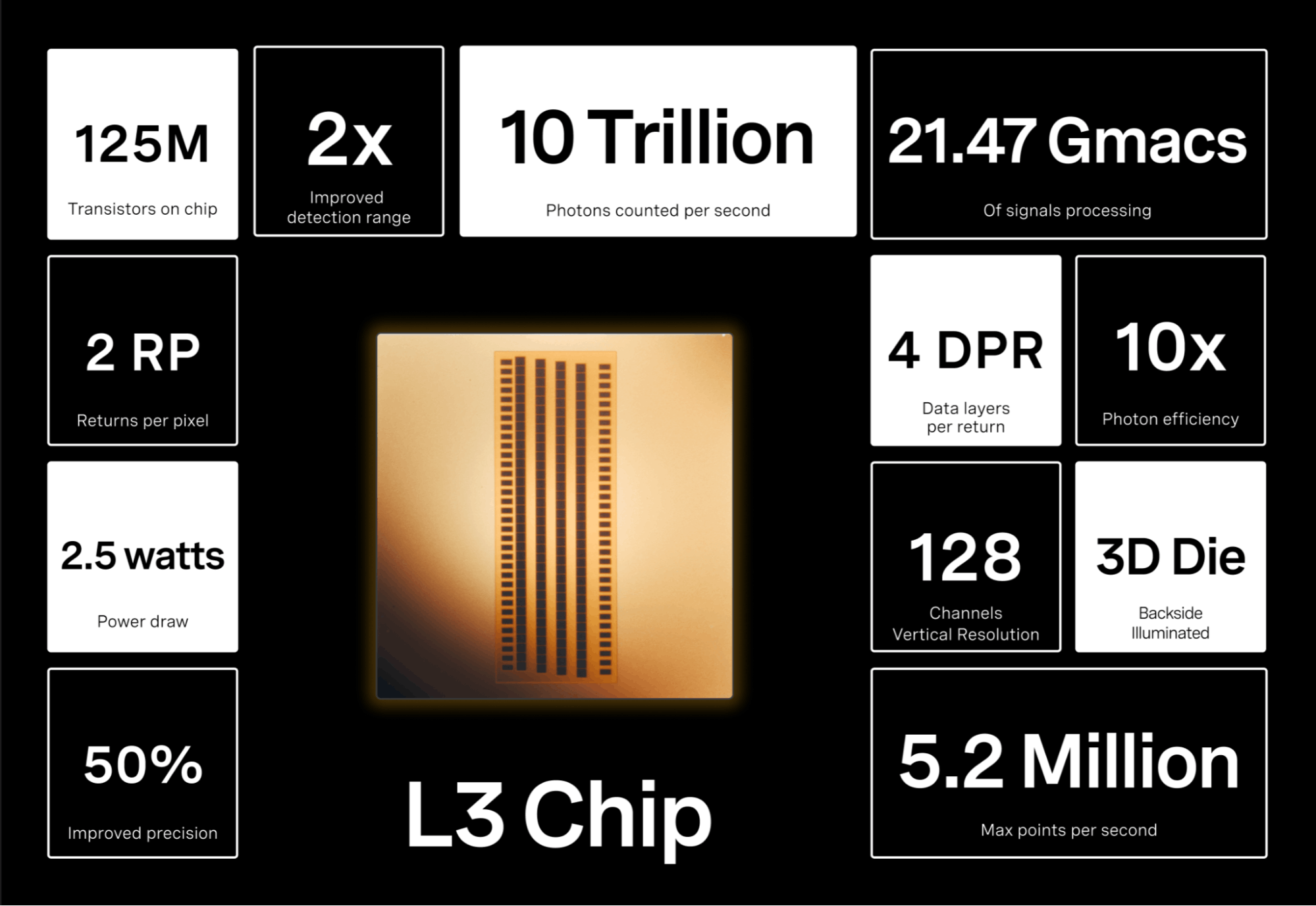

Introducing the L3 Chip: a giant leap for digital lidar

The L3 chip demonstrates the true power of digital lidar and represents a step change in sensor performance across our product lineup. Our CMOS design of L3 is fine-tuned for detection performance and efficiency, empowering our sensors to get more out of every photon. Fundamentally, the chip processes light much more efficiently, yielding the single biggest improvement in sensor performance we’ve ever brought to market.

Engineered with state-of-the-art 3D backside illumination, L3 packs an incredible amount of processing capability within a compact die area. This allows the sensor to output up to 5.2 million points per second while consuming less power than precious sensor generations. Equipped with L3, our REV7 sensors produce stunning point clouds and highlight physical details that remain invisible to other lidar technologies.

L3 continues our march forward in step with Moore’s Law. As a digital technology company, we leverage constantly improving silicon CMOS processes to design more powerful lidar SoCs. Digital engineering is a method widely used across the modern electronics industry, and with L3 it is making its biggest impact on digital lidar yet.

REV7: unleashing the power of L3

Today, we’re releasing our new REV7 sensor lineup, powered by the all new L3 digital lidar chip. With the L3 chip, our existing lineup is getting a massive upgrade:

10x increase in photon sensitivity

2x increase in range

50% improvement in precision

7x improvement in dark object detection

2x increase in points per second*

15% increase in maximum operating temperature*

10% reduction in power consumption*

No change in size or weight

*applies to OS0 and OS1 sensors

The Rev7 Product Family

Meet the OSDome

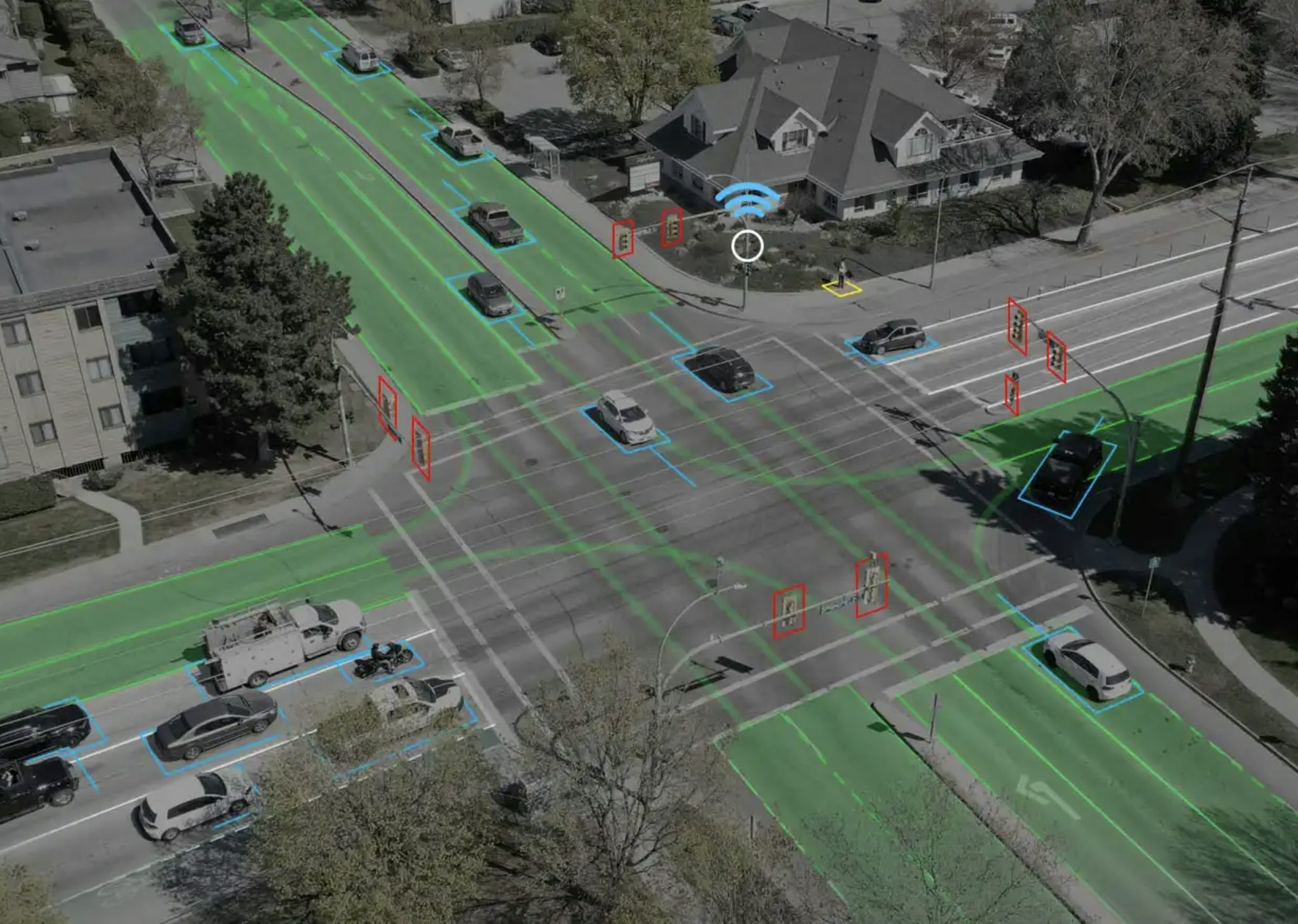

We are also adding a completely new sensor to our REV7 lineup: the OSDome. This new sensor is built using the same digital lidar module as the rest of our products and boasts a perfect 180° hemispherical field-of-view to provide complete situational awareness. The OSDome is equipped with the L3 chip and engineered for maximum detection performance in a compact design that supports discrete integration.

OSDome ceiling-mounted people monitoring

OSDome security integration

OSDome is the optimal solution for indoor spatial awareness. In security and people tracking, the sensor outputs high-fidelity depth data for detection and monitoring while reducing risk of liability from privacy incidents. Smart infrastructure installments like these benefit from the OSDome’s hemispheral field-of-view and best-in-class resolution to ensure full coverage of a space around the clock.

Warehouse robots, such as forklifts, leverage the floor-to-ceiling coverage to navigate tight aisles and critical obstacles on the floor or overhead. The compact design of the OSDome offers engineers flexibility when deciding on the ideal mounting location on the system.

Over 2x Detection Range

L3 is engineered with a 10x improvement in photon sensitivity, which translates to a doubling of detection range across our entire sensor suite. With the L3 chip, OS0 and OS1 are the longest-range sensors in their class, and the OS2 crosses the critical automotive threshold of 200 m range on a 10% reflective target, and now boasts a max range over 400 m.

REV7 OS2 - range beyond 400 m

The L3 chip’s boost in light sensitivity also improves every sensor’s ability to detect low reflectivity objects. The OS0, our ultra-wide view sensor, can now see objects farther and clearer than any other wide field-of-view sensor on the market – out to 35 m for a 10% reflective target. This same improvement to object detection extends to the OS1 and OS2, where customers can expect an incredible increase in detection probability on all manner of targets.

REV7 OS1 - black car at 15 m

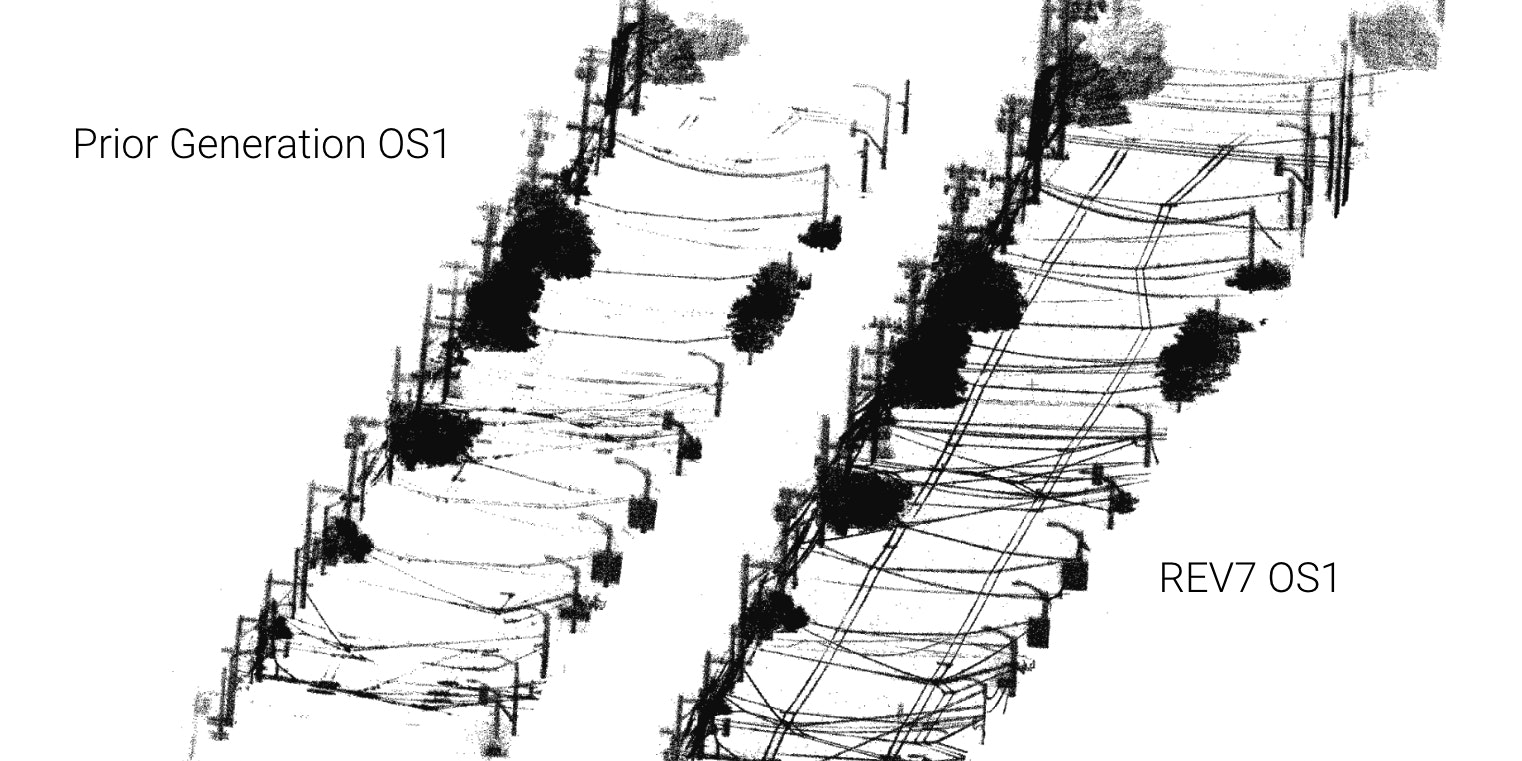

The combination of best-in-class resolution and upgraded detection of the L3 chip expands the effective range of our sensors, making it easy to visualize small and detailed objects such as power lines hanging across the road.

REV7 OS1 - visualizing fine physical details

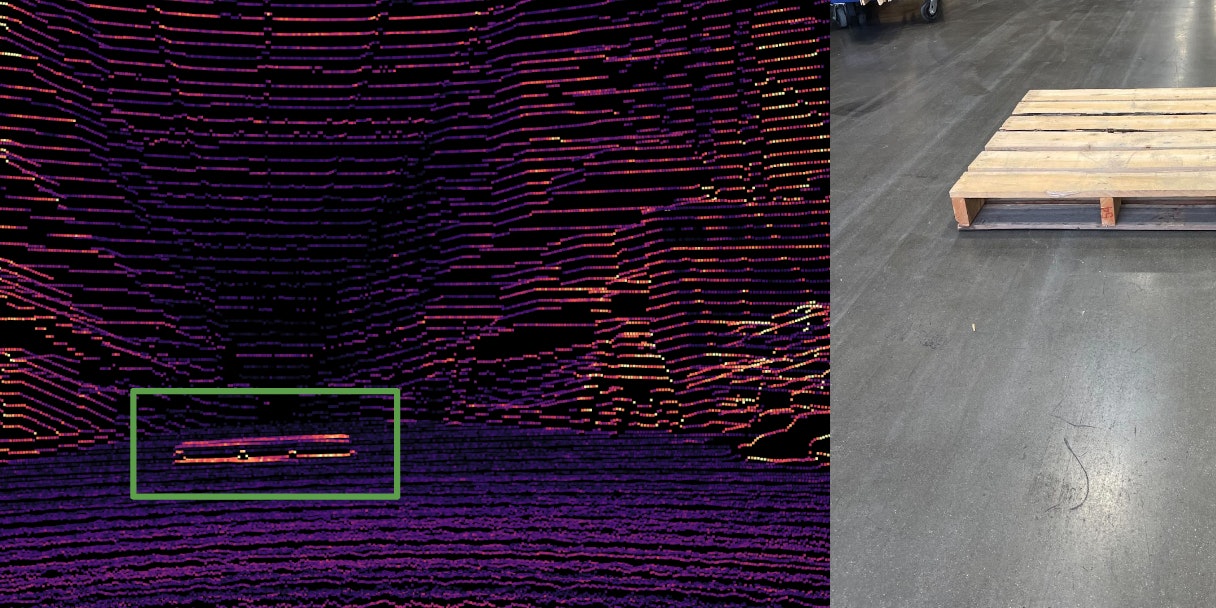

Or take this warehouse pallet, for example. With the detection upgrade of the L3 chip, the REV7 OS0 can not only make out the pallet on a shiny warehouse floor, but can also identify the small fork slots critical for safe lift operation.

REV7 OS0 - warehouse pallet at 5 m

Exacting Precision

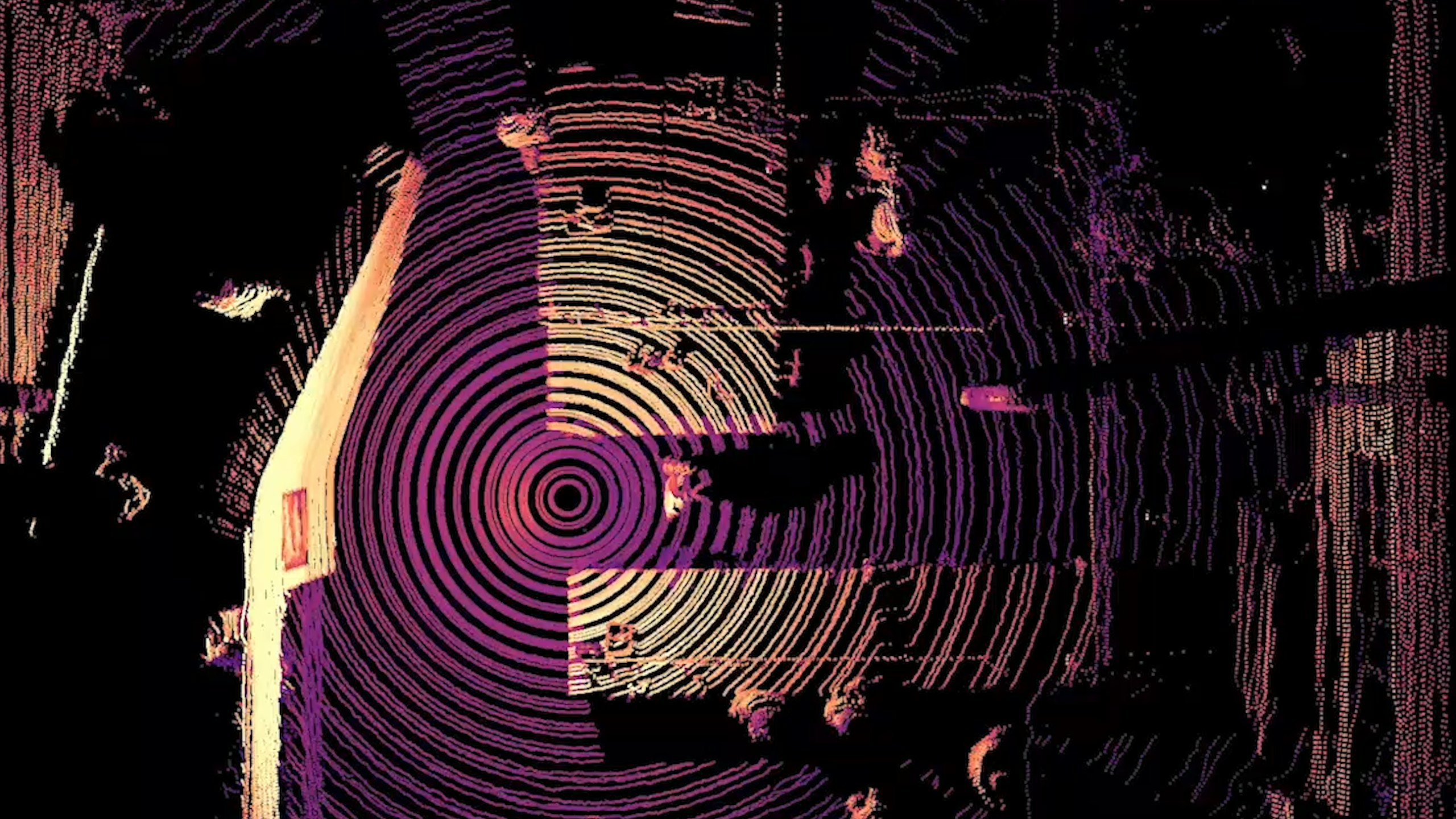

The L3 chip improves the range precision of all OS sensors. REV7 point clouds are sharper, providing a more accurate representation of surfaces and features such as walls, corners, and small objects. The L3 upgrade allows our sensors to represent the true range of each point to the sub-centimeter level.

REV7 OS0 - see walls accurately with +/- 0.5cm precision

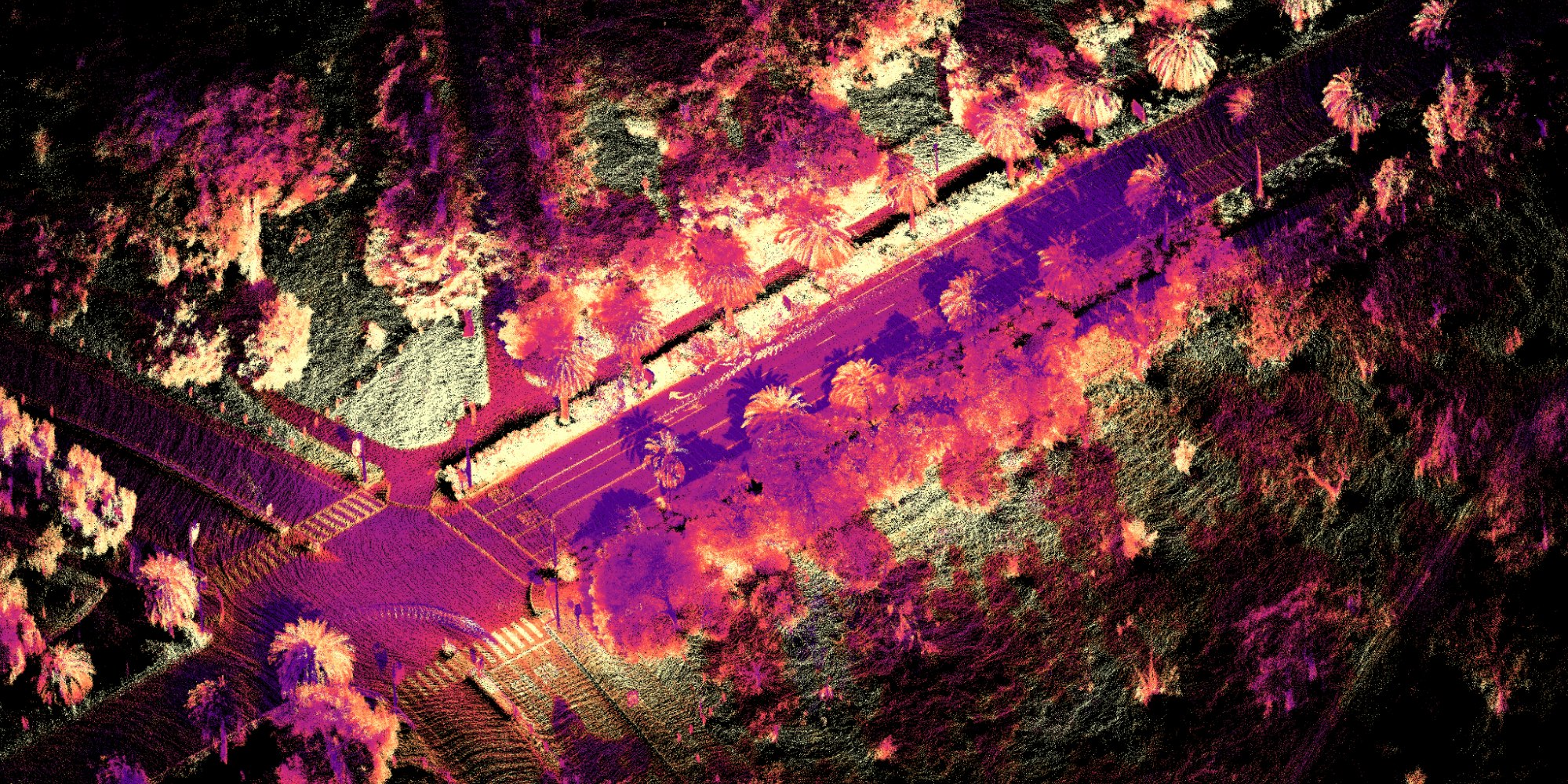

With fine-tuned precision and the highest resolutions on the market, customers can optimize SLAM algorithms and generate dense maps of warehouses, cities, or landscapes with incredible detail. REV7 precision unlocks a new world of possibilities for our customers. Detecting small details in the environment can help robots optimize their navigation paths and mapping companies increase the accuracy of their digital twins.

SLAM captured with REV7 OS2 - Palm Drive, Stanford University

Built for Real-World Reliability

Automation technology looks to be an unstoppable force in today’s world, proliferating across a wide range of industries, from autonomous vehicles and mining trucks to warehouse robots moving goods. In order to deliver the promised gains in productivity, safety, and profitability, many of these systems must operate at peak performance in some of the harshest environments on the planet. Compared to many of the complex and fragile analog lidar sensors available today, our simple digital architecture is easy to manufacture with high yield and holds up in rugged conditions.

Flyability Mapping Drone equipped with OS0 navigating Icelandic Glaciers

To further improve the reliability of our products in automotive deployments, we upgraded the construction of these sensors to include 94% automotive grade components (according to the Automotive Electronics Council). All of the performance and automotive upgrades in REV7 bring the impact of our L3 chip to autonomous vehicles and pave the way for safer, more efficient revenue-generating deployments.

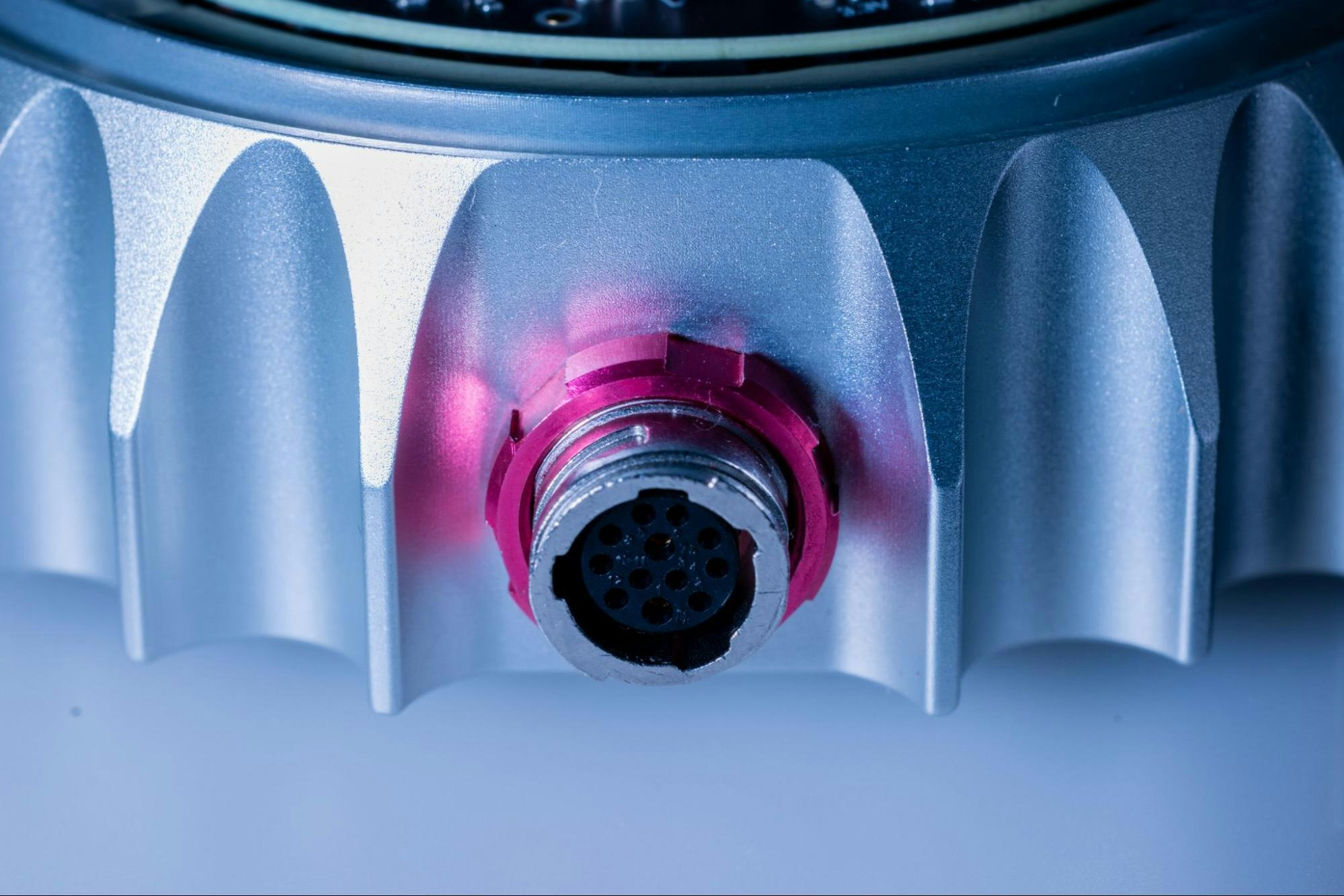

OS connector - now available with 1000BASE-T1 automotive ethernet

With REV7, we are building upon our foundation of reliability. Within the same digital lidar module, we upgraded dozens of components to operate at higher temperatures and withstand greater levels of shock and vibration. We’ve also upgraded the connector, extending our industry-leading IP68/69K ingress protection to cover a wider set of real world use cases.

Automotive Improvements

When designing REV7, we knew how significant the range, precision, and reliability upgrades would be for autonomous vehicle fleet deployments. To make these features even more accessible, we added 1000BASE-T1 automotive ethernet capabilities to the OSDome, OS0, and OS1. With auto ethernet communication protocol built in, our sensors are now compatible with an ever increasing array of off-the-shelf automotive grade compute and networking hardware, saving customers integration time and money.

Digital is the answer, and L3-powered REV7 proves it

The L3 chip delivers on the promise of digital lidar. Without overhauling the entire sensor design, we are able to bring step-change upgrades in range, detection, precision, and reliability to customers in a broad array of industries.

The rollout of REV7 is a huge leap forward in making 3D lidar more performant and affordable as we continue to climb the curve of Moore’s Law. And therein lies the power of digital lidar. It’s only going to get better from here.

We would love to support you in your automation journey any way we can. For more information about the L3 chip, REV7 sensors, or to schedule a demo of these new products, please reach out to us here and be sure to tune into our REV7 launch webinar.